Aramid fiber fabric and carbon fiber fabric usage with epoxy resin

The mechanical properties of these resins seem promising, more research activities are necessary to compare the mechanical properties of composites made with bio-based resins to those of commonly used epoxy resin composites to guarantee a safe design and the structural integrity of the components. Furthermore, the possibility to use these resins for vacuum infusion processes should be also properly investigated, since the preliminary studies reported an increase in the viscosity that could limit the use of vacuum infusion. The mechanical characterization of bio-based composite laminates is therefore fundamental and of utmost interest among universities and industry, since it represents the most promising way to lower the carbon footprint for manufacturers by using the same production technology. Few works in the literature aim to compare the mechanical properties between composite laminates made with epoxy and bio-based epoxy resins. Yashas Gowda etal. compared the mechanical properties of a laminate made of hybrid basalt and areca fibers. Tensile tests and flexural tests showed a decrease of ~5% for the tensile and flexural strengths and tensile and flexural moduli for the composites prepared with bio-based epoxy resin.

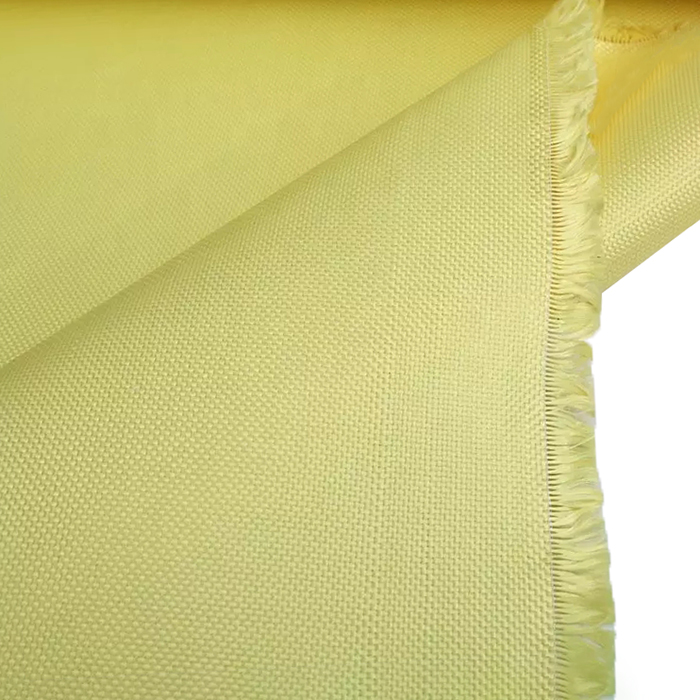

Aramid fiber fabric(para-aramid)

Aramid Fabric is one of the most commonly used composite materials,it has many outstanding characteristics:high toughness,high strength,flame resistant,heat resistant,bullet proof and shock-absorbing.Aramid fabric is applied in fire-fighting suits,flame proof gloves,medical equipments,military products,aerospace and spaceflight and other different fields.

Aramid fiber fabric

It is weaved mainly by para-aramid fiber 200D 400D 600D 800D 1000D 1500D 3000D. VVeave pattern including plain,twill,satin.lts application mainly including aerospace,bulletproof vest,electromechanic equipment,building reinforcement,auto and sports equipment.

| Product Type | Aramid fiber woven fabric |

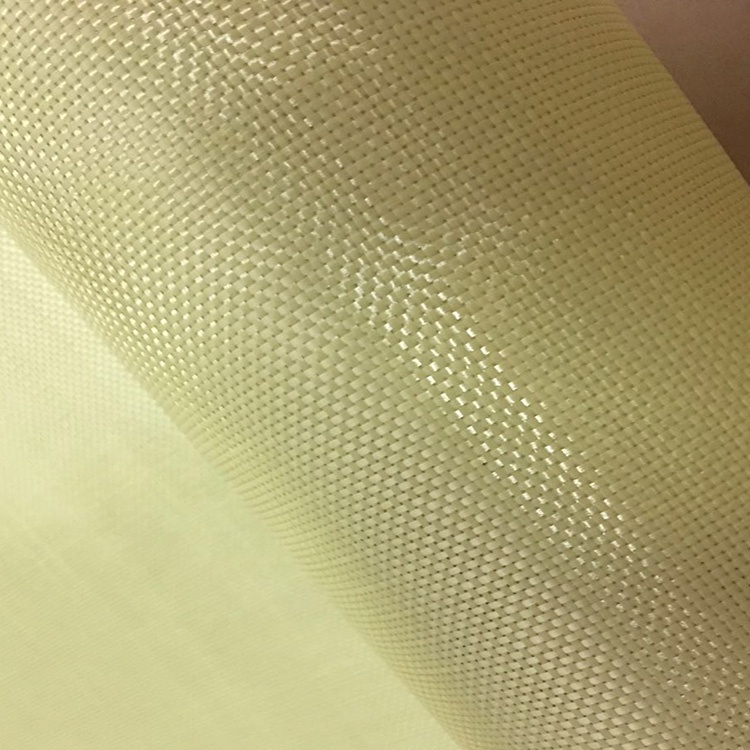

| Material | 100% para-aramid |

| Yarn Type | kevlar 29 Dupont yarn |

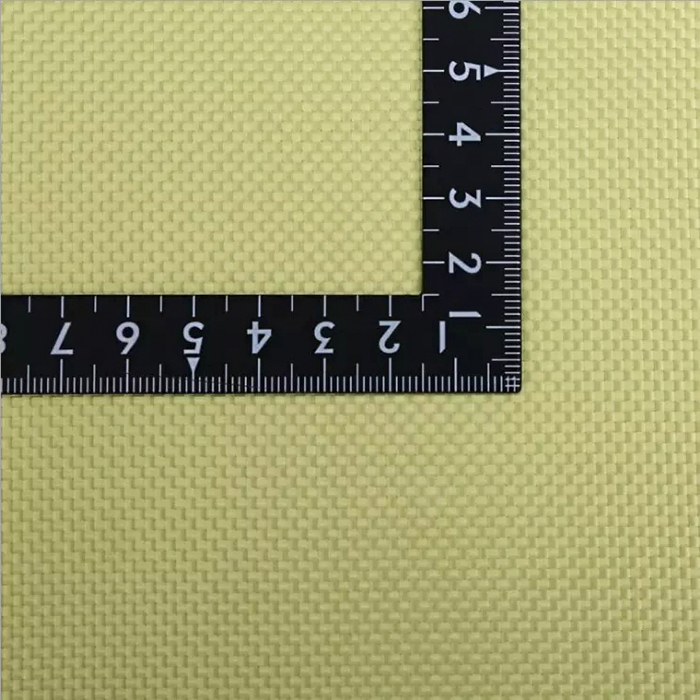

| Weave pattern | Plain |

| Warp Yarn | 1500D |

| Weft Yarn | 1500D |

| Width | 1500mm |

| Weight | 200+-5g |

| Thickness | 0.26+-0.02mm |

| Modulus | 590 gpd |

| Breaking strength | 75 lb |

| Elongation | 3.35% |

| Length | 100m/roll |

Aramid fabric weaved by 1500D para-aramid fiber with yellow color.